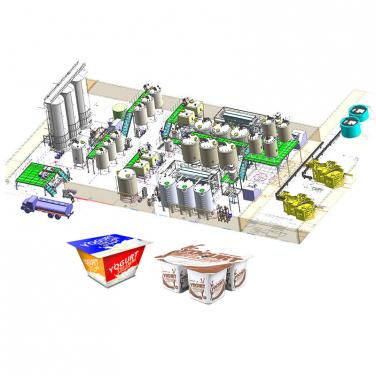

Innovation and improvement of yogurt production line -- here is the best way to mix yogurt

Mar 17, 2022

Yogurt consumption is booming all over the world. But yogurt is a sensitive product, the production process can not be too heavy. Choosing the right yogurt production line equipment will be very different.

Whether for health, convenience or taste, consumers around the world are eating more and more yogurt. Traditional large consumers such as France and Turkey are still growing strongly, but consumption is now growing rapidly in developing countries.

Although tastes vary from local favorite yogurt to Greek style yogurt to sweet yogurt with solid ingredients or flavor - a common challenge for manufacturers is that yogurt is very sensitive to the processing of yogurt production line equipment. If mixed or stirred too hard and too fast, the yogurt may reduce to an unsatisfactory liquid consistency or separate to form a liquid layer.

Added ingredients, such as fruit slices, are also fragile and need to be handled gently to maintain their shape and texture.

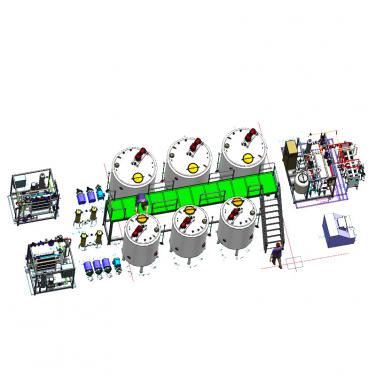

In order to meet these challenges, beyond provides advanced homogenizer equipment. Unlike many general models, it is specially optimized for the needs of the yogurt industry. In general, the homogenizer is very mild to its processing components, which can improve quality, improve food safety and reduce waste.

During yogurt production, the agitator blades do not move. On the contrary, the liquid is mixed when flowing through them. Its main advantage is that the blade is bent evenly and the angle is shallow to ensure that the product is gently mixed. The blades are also thicker than other mixers, making it easier to clean. Its smooth design helps prevent fibers and particles from getting stuck.

The welded structure of the mixer further promotes hygiene and eliminates uneven surfaces that may intercept food particles. The CIP system is always kept perfectly clean after CIP is manufactured. Eliminating the risk of human error, CIP is very effective and saves time because the operator does not need to dismantle the mixer for cleaning.

In order to successfully realize the ambition of producers, we need to have a thorough understanding of the science behind yogurt production.

Although the homogenizer has a relatively long history of use, we have made significant improvements in recent years, which are based on a careful study of how to optimize the performance of the mixer to meet the needs of individual customers.

Le dernier:

Changes and challenges: the juice, nectar and still life beverage industry is facing an uncertain world

La prochaine:

Business area - food production line turnkey engineering

Nouvelles

Produit chaud