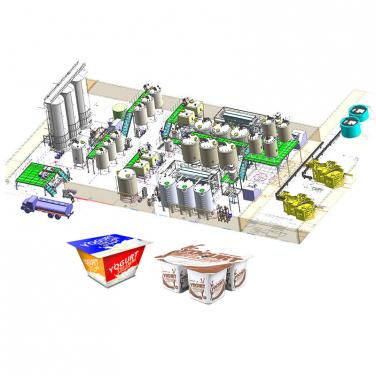

We provide comprehensive maintenance to ensure the reliability of your food production line. Our skilled service engineers ensure that everything from a single production unit to the whole factory is in good condition. Maintaining equipment is only a wise long-term investment. Through our maintenance services, you can ensure the best return.

Our proposal

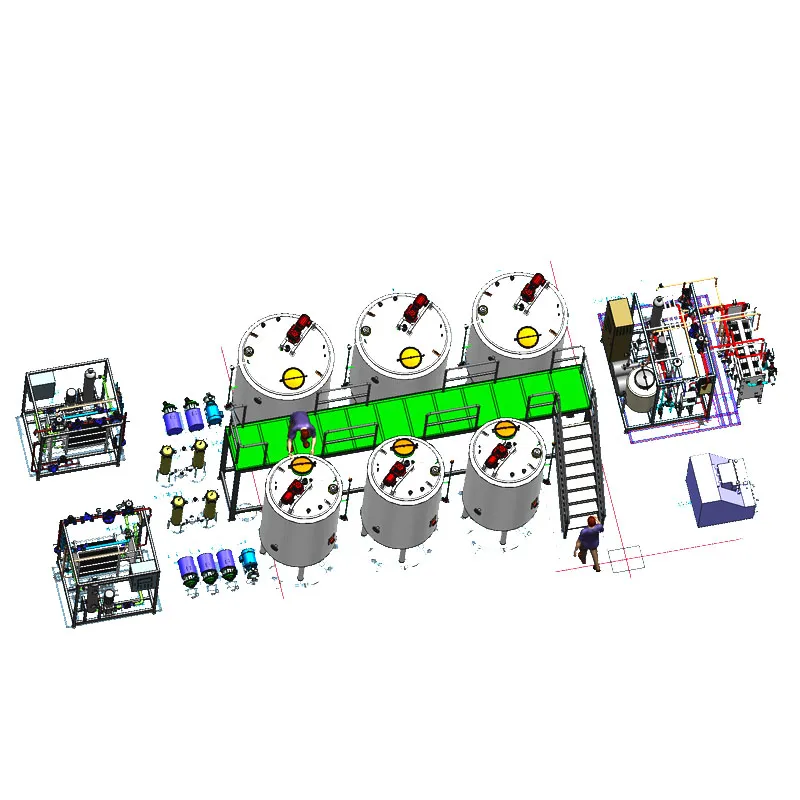

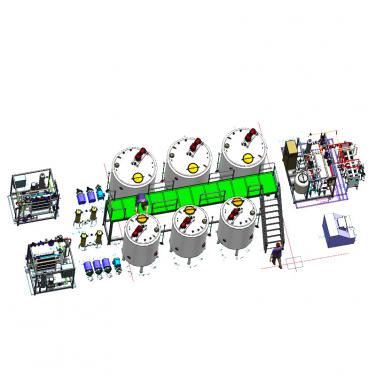

Your food line is designed to operate with the highest performance and reliability. Since your equipment operates in harsh conditions, it is necessary to regularly inspect and replace parts in key areas. The core of our maintenance service is our maintenance system. Based on the reliability centered maintenance method, we provide the correct combination of scheduled, condition based and corrective maintenance strategies. This is a platform for continuous improvement, based on the feedback of our global installation group.

Through our equipment maintenance, we will take the initiative to protect your food production line. We minimize the risk of downtime and predict failures even before they occur. If there is a problem, our skilled service engineers will solve the problem in the fastest way and prevent it from happening again.

Optimize and support your maintenance planning and execution

Extend uptime by quickly resuming full production

Ensure uptime and save money in the long run

Through preventive maintenance, you can minimize the number of unplanned stops and the duration of each planned service stop. This proactive care greatly reduces your total production costs. Let our skilled service engineers solve the problem before it occurs, so that they can be completely at ease.

Predictive maintenance with condition monitoring enables us to predict failures before they occur. Through real-time monitoring of key equipment areas, we can identify machine function deviations that may lead to machine stop or failure.

With our on-site support, you can easily and directly access our global network of maintenance expertise through a dedicated team, whether on-site or remotely. Whether it's proactive employee coaching or immediate support, we have the ability to meet your food production line operational needs.

Provide proactive care and guidance to employees

Seasonal or organizational change needs

Get instant support in the most convenient way

Support your maintenance and production planning decisions from an external perspective

Remote support

Remote support provides you with 24x7 technical, operational and automation support, no matter where you are. When you encounter problems, just call us and our experts will provide you with immediate help through the communication channel you choose. At any time, the goal is to quickly resume production.

Solve problems faster

Reduced cost of troubleshooting

Minimize unplanned downtime

Reduce the operation risk of food production line

Equipment evaluation

Through our equipment evaluation, we check, verify and calibrate your equipment to ensure its compliance with food safety regulations and ensure product quality. At the same time, we help you improve performance and reduce maintenance costs.

Benefits:

Minimize unscheduled downtime of food production lineEnsure food safety and product quality

Reduce maintenance costs

Ensure efficient and energy-saving production

Support your quality management system

maintenance management

Through our maintenance management, we provide maintenance assessment to help you identify areas for improvement. The next step is our maintenance management service to help you complete the maintenance process and ensure the best performance and reliability.

Benefits:

Balance cost, risk, and performance against your strategy to achieve the best maintenance solutionSimplify and maintain the management of food production line

Gain insights through global benchmarking